ORC – Organic Rankine Cycle

Don’t waste energy, convert it !

At Helec we have extensive experience delivering 100% cogenerated energy with both large domestic and commercial CHP technology to deliver thermal heat & electrical power for onsite consumption. This has many benefits, with the primary one being good financial savings with reduced operating electrical charges.

However, if the thermal heat cannot always be used while the CHP is producing power then the overall return on investment and ultimate savings are likely to be reduced.

The Solution – ORC

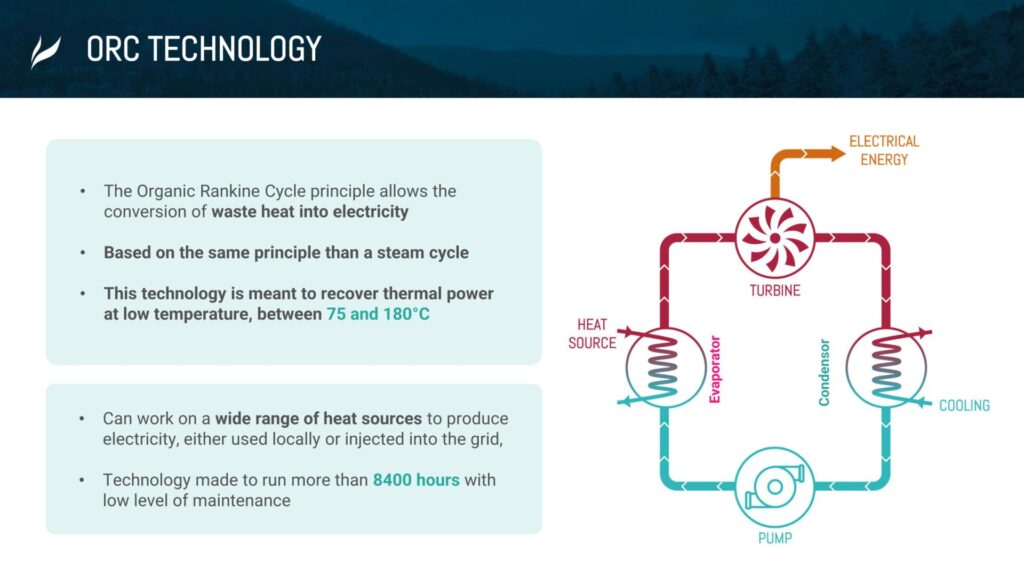

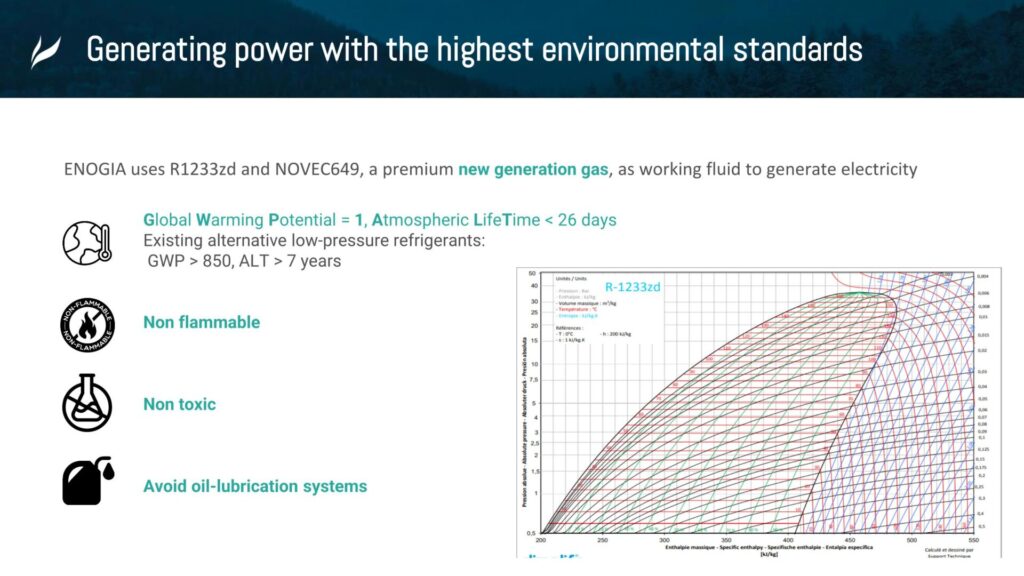

ENOGIA uses the well known principle of the Organic Rankine Cycle to convert waste thermal heat (which would ordinarily be dispersed out through a heat dump radiator if not required) into a usable onsite electricity.

These ORC modules can work on a wide range of heat sources to produce electricity, which can be used on-site, or potentially re-injected back into the national grid.

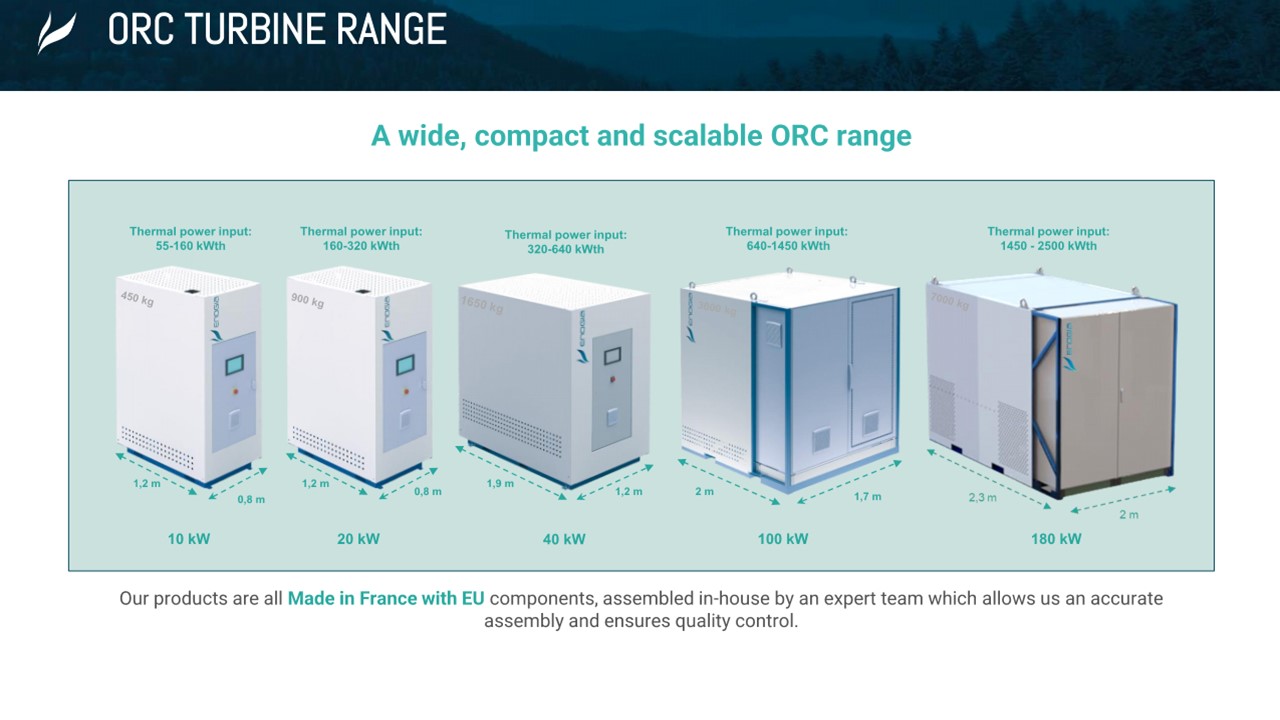

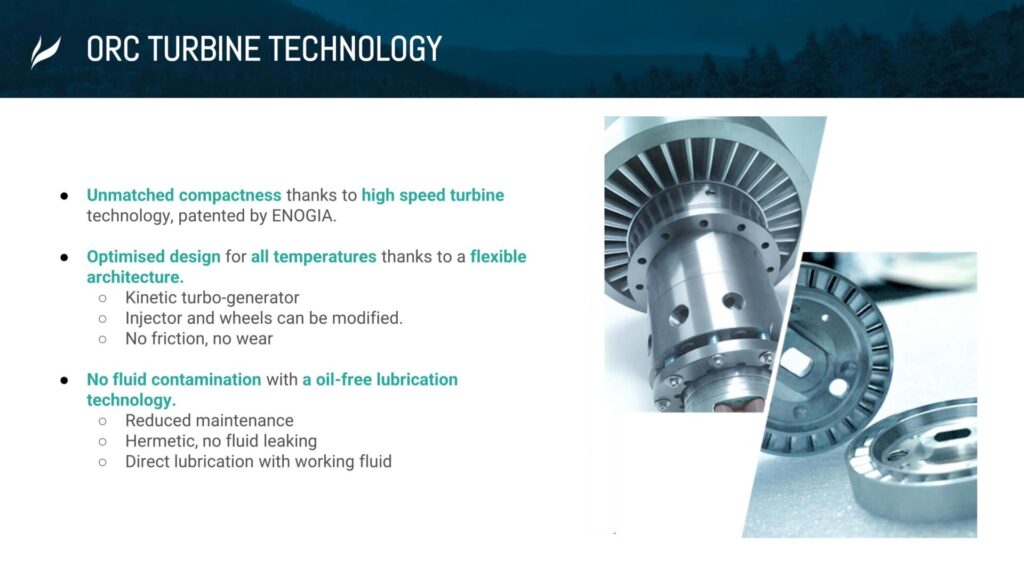

Our business partner ENOGIA has engineered a unique high speed turbine technology which is able to integrate with our CHP units to take the unwanted thermal engine heat and generate between 10 to 180 kWe of “additional free” electrical power.

Furthermore, Enogia engineers can design custom expanders or other turbomachinery, should you need a device that is not available “off the shelf”.

Helec has many years’ experience with a variety of Combined Heat & Power solutions through a multitude of fuel sources and the recent Government and Global decision to drive down emissions to ‘NET Zero’ by 2050 and strive to source low carbon “green” fuel sources for heating & power solutions has prompted Helec to engage and partner with more like minded manufacturers in the transition to a NET Zero target.

Technical Specification of the ORC

How the ORC System Works

The Enogia Organic Rankine Cycle systems take in and utilise the unused thermal energy produced from a variety of thermal generating applications such as;

>Combined Heat & Power units

>Biomass Boilers & Pyrolysis Gassifiers

>Gas engine Gensets

>Geothermal heat source pumps

The engine jacket water & exhaust heat that would usually be transferred away & discharged via the exhaust stack & a heat dump radiator (in low thermal heat periods) is diverted via a 3 way valve which is passed through the patented kinetic micro-turbines to generate electrical power.

The returning flow temperature is then cooler, ensuring the primary equipment that it originated from remains in operation (essential for continued CHP onsite power benefits) and deliver the client the optimum fuel efficiency.

(Note: The output kWe power potential of the ORC will be dependent on the input kWth thermal power being delivered by each application – see below)