Biogas CHP

At Helec we can supply and install from a wide range of sized Biogas fuelled Combined Heat & Power systems for commercial use to provide much needed low carbon benefits. Biogas cogeneration systems are most typically suited to locations where there is a ready supply of organic waste material available to produce the Biogas (Biomethane) fuel source through processes such as Anaerobic Digestion. These AD processing sites are usually located near agricultural farms, food processing sites and large scale waste disposal locations in order to minimise the transportation costs and manage the quality of ‘raw fuel’ being delivered.

Helec has over 17 years experience designing, installing and maintaining CHP systems across the UK. Our technical team can provide full applicable feasibility studies as well as looking to undertake a complete design and build installation package of a Biogas CHP system working from 30kWe units through to 1mWe and more.

If you wish to know more about how Helec can look to help with your Biogas enquiry, then call the office on 01934 862264.

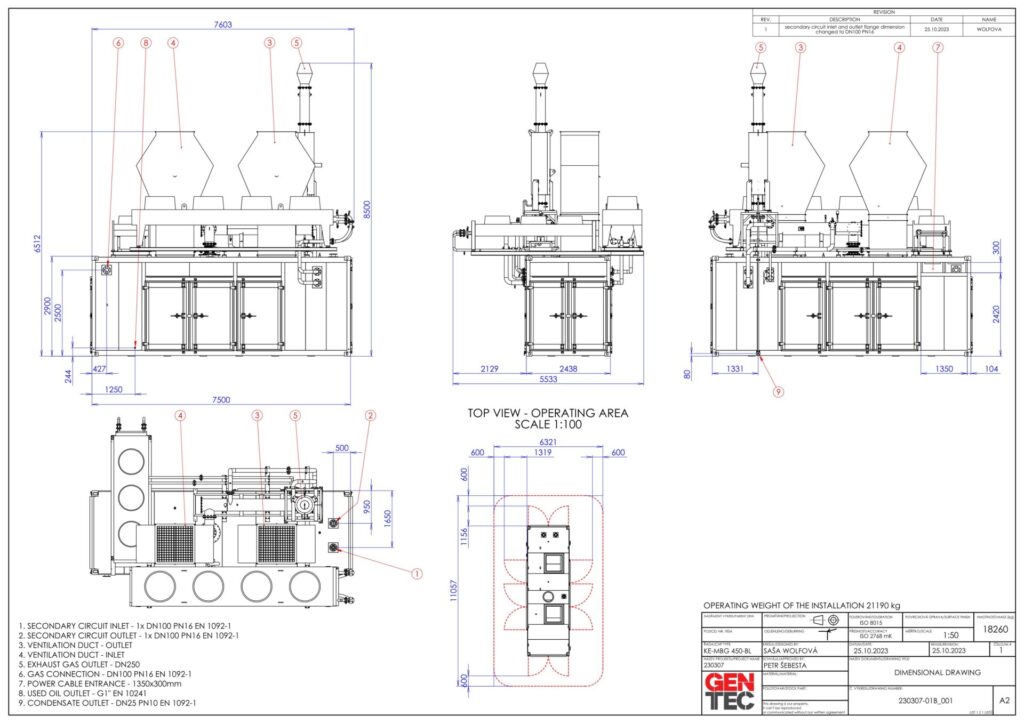

Alternatively, browse through our range of Biogas CHP products via our CHP partner Gentec, or continue to read more information about Biogas and the AD process below.

Biogas cogeneration/Combined Heat & Power (CHP) units usually run on a methane gas that is created by an anaerobic digestion process (AD). These microbes feed off carbohydrates and fats, normally in animal waste producing methane and carbon dioxides as metabolic waste products. This can be harnessed and processed for use as a gas fuel to run Combined Heat & Power engines and is classed as a source of sustainable energy as it originates from organic material that has been created from atmospheric carbon by plants grown within recent growing seasons and then eaten and digested by animals (normally cows, pigs and chickens) to produce the waste.

The prime benefits for AD and Biogas generation is the production of a renewable power on site through combined heat and power cogeneration which reduces the need for national grid electrical power dependency, lowering electrical bills, reducing landfill bills whilst providing a useful diversity for the animal, & or food waste to produce low carbon fertilizer and provide a reduction in local carbon emissions.

The power generated on site can be a revenue source as it is exported back into the Grid, used to run plant machinery and thermally heat the AD tanks to assist with the required temperature needed to eliminate disease and heat the hot water required for cleaning and processing.

There are many positive aspects to Biogas Combined Heat & Power cogeneration, however be mindful the CHP engine is designed to have a consistent gas quality supply in order to run smoothly and this can be contaminated at the process stage by a variety of reasons, namely excessive water dilution in the tanks, cleaning agents creating Siloxanes (a variation of silicon) to name a few.